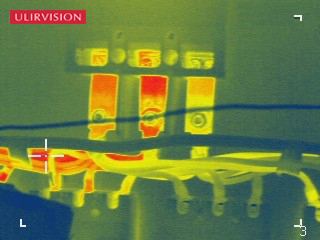

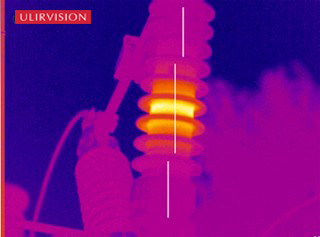

There are lots of power equipment faults and most of them would give off heat. In the power industry, the thermal imaging camera has been used for thermal defects detection on electrical equipment and lines to ensure their security operation for a long time.

Use our thermal imaging equipment to do the following power equipment state inspection and fault diagnosis.

1. Detection Object: Transformer

Faults Can Be Detected: Transformer tank overheating, eddy current overheating, a poor connection of the up and low end of high-low pressure bushing, oil-filled bushing lack of oil.

2. Detection Object: Lightning Arrester

Faults Can Be Detected: Inner damp of various lighting arrester. Inner component aging and nonlinear characteristics variation.

3. Detection Object: Capacitor

Faults Can Be Detected: Overheating of various capacitor, poor oil-insulation of coupling capacitor and lack of oil.

4. Detection Object: Circuit Breaker

Faults Can Be Detected: diversion body overheating caused by poor connection, inner damp of insulation porcelain jacket, poor connection of moving and fixed contact, lack of oil, poor connection of middle contact and fixed state base.

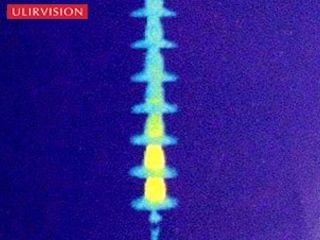

5. Detection Object: Insulation Chain

Faults Can Be Detected: Bad porcelain, dirt, low value and zero value which leads to insulator fault.

6. Detection Object: Instrument Transformer

Faults Can Be Detected: Insulation fault, oil and iron core fault, inner connecting fault and lack of oil.

7. Detection Object: Electric Generator

Faults Can Be Detected: stator-core insulation defect, poor connection between stator bar contact, electric brush and collecting ring.

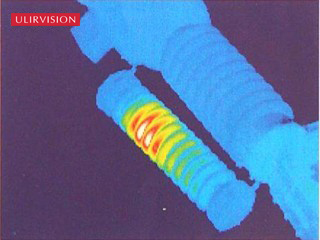

8. Detection Object: Power cables and wires

Faults Can Be Detected: Diversion overheating fault caused by poor connection of three-phase outlet connector of cable head, diversion overheating fault caused by poor connection of internal connector, partial insulation fault of cable head, cable bushing fault, which lead to wire faults and poor quality of wire, wire insulation faults.

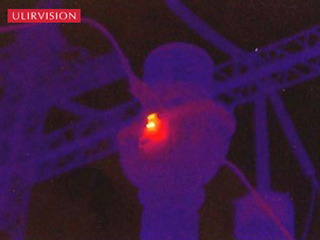

9. Detection Object: Disconnecting Switch

Faults Can Be Detected: Porcelain pole surface dirt and cracks, insulating coating degradation and poor insulation contact.

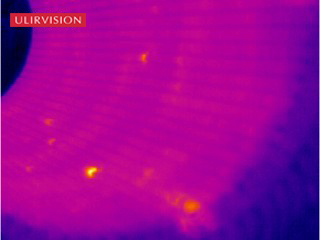

10. Detection Object: High-voltage transmission conductor and pressure pipe

Faults Can Be Detected: Poor joint contact.