Ordinary building diagnosis often has great difficulties for people. The floor is relatively high, the indoor items are piled up too much, and there are plants covering the outside, those will all increase the difficulty of building diagnosis. Sometimes it is even necessary to dismantle some of the buildings to troubleshoot the problem. But infrared cameras can handle most of these difficulties. As predictive maintenance and diagnostic tool, a thermal imaging camera is an economic choice, especially it can check buildings without causing any destroys to the building. Thermal defects such as lack of thermal insulation material, thermal bridges, air leakage, and moisture all that lead to the wall temperature changes can be detected by our thermal imaging camera, thus preventing the potential hazards, these include the following four situations:

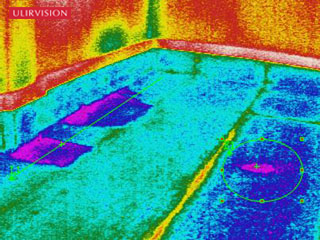

Insulating layer defects or lack will cause severe results, such as leakage, material sag, circuit damage, and so on. Therefore, this problem should be taken care of. Using a thermal imaging camera, such problems can be discovered easily. And engineers can handle problems more efficiently.

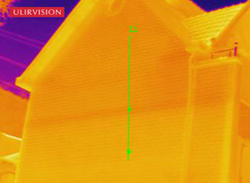

Poor sealing will cause leakage, and the air will go through the cracks which will lead to regional temperature decreasing, energy consumption increases, and dust setting. This leakage is difficult to find without a smart gas leak detector.

Once the water penetrates into the building structure, it will cause serious consequences, ranging from increased energy consumption to building mildew which will not only destroy the building structure itself but also the goods put in the building.

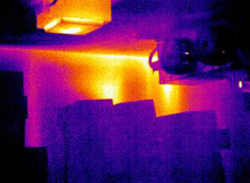

This will also cause a lot of problems, and people's safety could not be ensured. However, it’s hard for people to find such a problem. But thermal imaging cameras can find it through infrared technology.